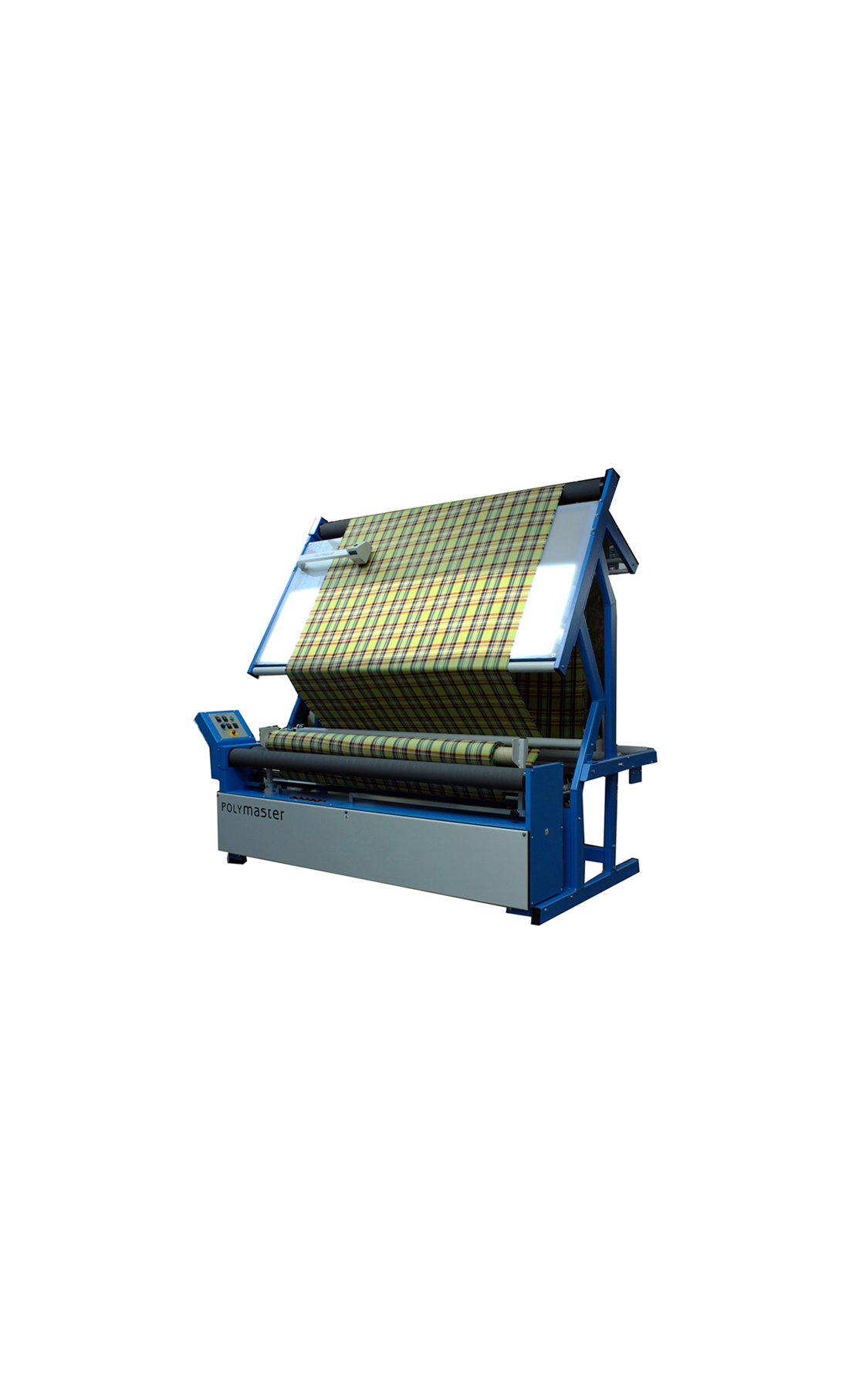

IM.

Polymaster has long since seen the requirement for a full Inspection Machine, which can meet the exacting needs of fabric quality assessment without the traditional over complication.

The result is simple to set up, operate and at a price that ensures a quick return on investment. The polymaster design of modular construction allows you to specify a unit, in size and options, to meet your exact requirements, from basic examination to in-depth detailed fault data collection. Coupled with our Fault Logging Software the IM is a powerful inspection machine capable of producing detailed reports and able to link to external cutting software.

With automatic edge-guidance as standard, roll presentation is always at its best.

Also available as the full size IMR inspection machine the IM-Range offers unrivalled inspection surface area and high levels of illumination.